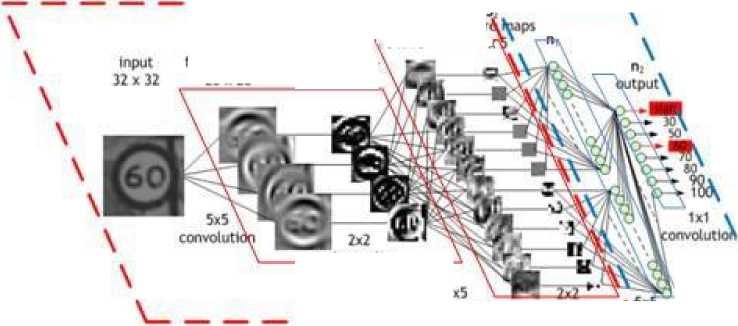

The board image is captured by a high-precision color industrial camera, and the image is processed by a convolutional neural network algorithm to intelligently determine the defective components and solder joints.

Suitable products: Motherboards: TV motherboards, server motherboards, PC motherboards Power supplies: pan power boards, adapters, industrial power supplies, energy panels Controls: industrial control boards, home appliances control boards, meter categories: dashboards Others: automotive electronics, communications 5G Wait

Items inspected after wave soldering furnace:

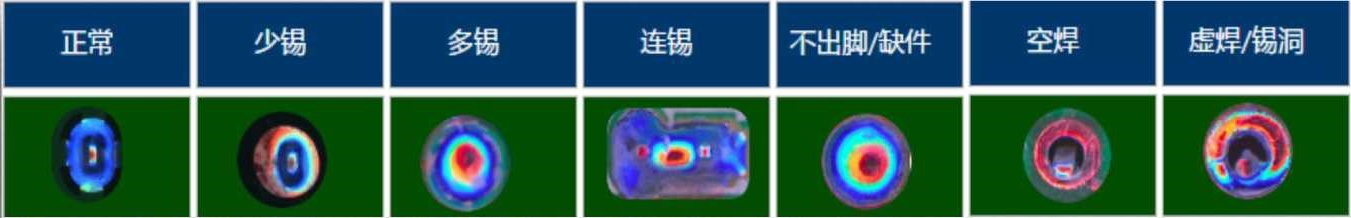

*The solder joints under PCBA (bottom board/B side/solder surface) are less tin, more tin, continuous tin, no lead/missing parts, empty soldering, virtual soldering/tin holes; device offset, tombstones, missing Pieces, counter pieces, crooked feet, wrong pieces;

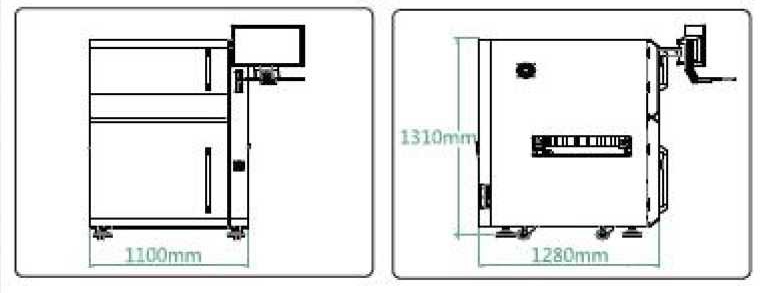

Equipment architecture: online design

Bottom-illuminated structure design simplifies the process and shortens the overall production time

Automatically enter and exit the board, save manpower and improve efficiency

External nail-free design, simple and beautiful

Lightweight and simple, flexible production line layout

Marble platform to maintain the stability of the equipment

Installation position: behind the wave soldering furnace

Detect solder joints through AOI instead of manual visual inspection, save visual inspection personnel, save costs and improve quality

Down-illuminated AOI, no additional flipping action is required, improving efficiency

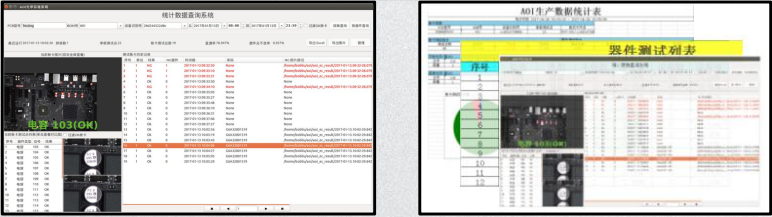

Data traceability, SPC data statistics, data traceability

Guide personnel to repair quickly to avoid missed inspection

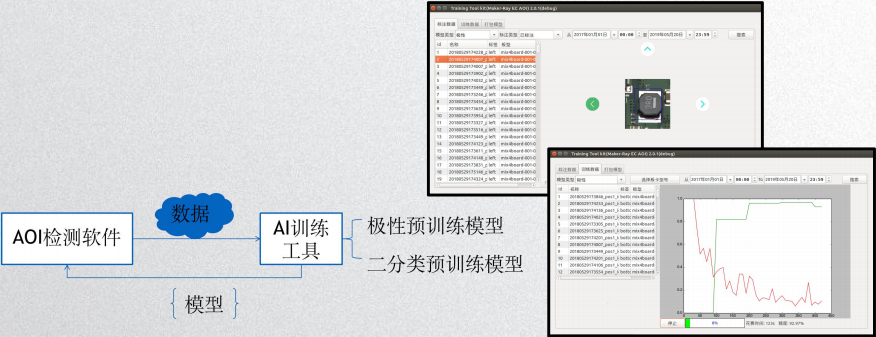

1. Deep learning algorithm, simple programming, high detection rate;

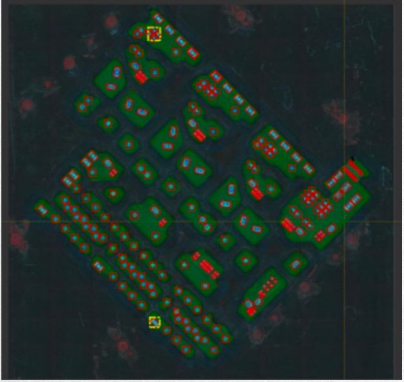

2. Achieve one-key programming, automatic search of component solder joints, and fast programming;

3. General intelligent model, training based on big data;

4. Path planning reduces the number of FOV shots and shortens the shooting path;

5. Diversified models, supporting remote plate making, mixed plate production, and online testing;

6. One-click data export, comprehensive and detailed statistical reports, data docking with MES system;

7. Facing Industry 4.0, centralized management reduces personnel;

8. Practical training tools, self-learning and evolution of equipment;

Product Feature 1: Core Algorithm Innovation

Convolutional neural network algorithm is used to solve the two traditional algorithm pain points: long programming time and high false alarms

Intelligent algorithm: Based on deep learning of big data, one-click search for component solder joints, automatic programming, intelligent identification of defective component solder joints

Traditional algorithms: color, edge, feature and other detection and comparison algorithms, etc. OCR text recognition algorithm

Product feature two: easy to learn and operate

Deep learning algorithm, simple programming, one-click automatic search of component solder joints, intelligent judgment of poor, fast programming speed.

Intelligent adjustment algorithm: CAD, Gerber, etc. files are not required, and the solder points and chip materials can be automatically selected and parameters can be set

Parameter broadcast function: One-key synchronization of similar solder joint algorithms and parameters, greatly reducing adjustment time

Online programming: can realize "measure while adjusting", no need to stop the line;

Programming time: 10-20min; debugging time: 10-15min

Short line change time, direct call to existing format files, no need to repeat adjustments

Product feature three: strong detection ability

The model based on big data training has high recognition accuracy of components, strong detection ability and generalization, and can correct alarms caused by diversified solder joint deviations and reduce false alarms.

On the BOTTOM surface under the wave soldering process, the solder joint components vary greatly, and the algorithm is required to recognize different NG and different OK, and cannot miss the test

Convolutional neural network is more similar to the way of human discrimination. It can effectively identify diverse test scenarios and reduce the false alarm rate while ensuring the detection rate.

Strong ability to identify fuzzy features and effectively detect tin holes on solder without interference from pins and devices

Strong generalization ability, compatible with multiple shapes of solder joints, diversified solder joints, slight differences in color, irregular solder joints, and low false alarm rate

Product feature four: fast detection speed

Genetic algorithm path planning

Fewer FOVs-the positions without solder joints are not shot, reducing the number of FOVs and improving efficiency;

Shorter photo path-reduce FOV jumps with a large span, further saving time;

More suitable imaging position-avoid soldering points at the FOV connection to ensure test results;

GPU image parallel processing, data running faster;

Product feature five: multiple detection modes

Combining with the diversification of factory production modes, design a variety of testing modes to support testing of multi-model production and alternative materials;

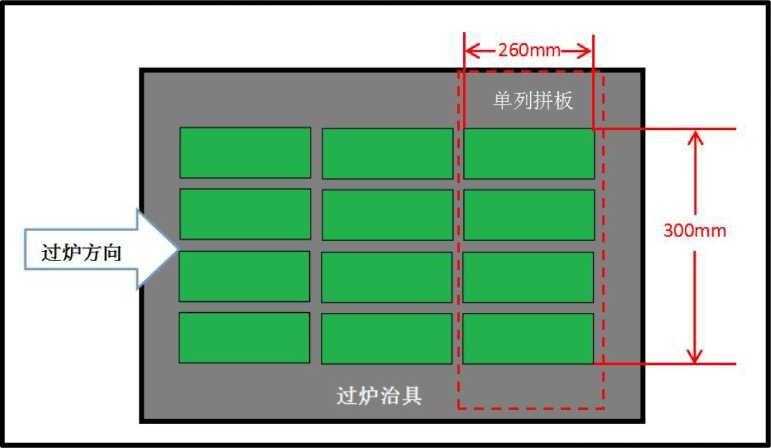

Support puzzle detection Support mixed board detection BadMark skip mode

Product feature six: detailed test data

Test data is retained in real time, and detailed data reports can be exported, which is conducive to process improvement and production traceability;

The camera automatically reads the barcode (barcode, dot code);

Data integrity: including overall statistical data, and all inspection information of each inspection board;

One-click export: easy to trace back, data can be effectively connected with the MES system

Product feature seven: centralized management, remote service

Support remote programming, debugging, management, save time for changing lines, and support one-to-many re-judgment

Remote debugging, control and centralized management: reduce work interruption and improve work efficiency

Remote offline programming, advance programming

Remote support: quick response to maintenance

Re-judgment workstation: one-to-many re-judgment

Product feature eight: wide detection range

AI tool training model, equipment end can independently train special devices, can automatically identify, improve detection accuracy

Quickly learn new devices and solder joints

Debug the program, adjust the threshold to treat the symptoms but not the root cause. Through training, let the equipment recognize the different forms of the device, and truly reduce the false alarm rate

Rapid iteration and continuous upgrading of testing capabilities

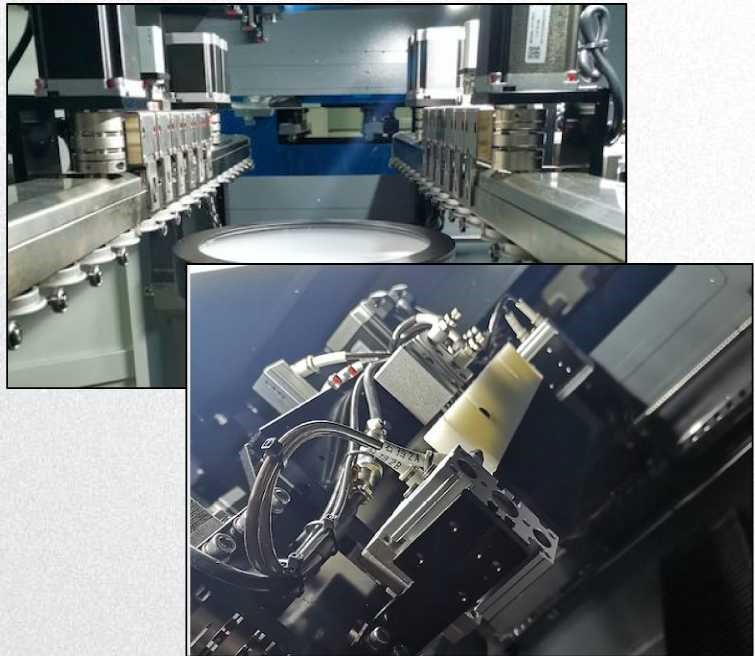

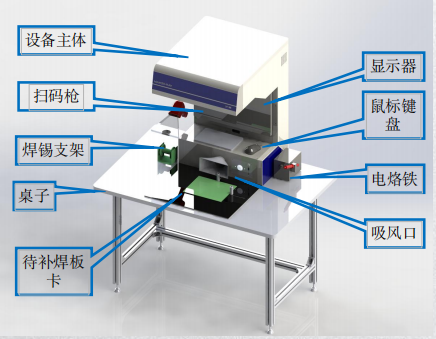

Product feature nine: equipment details

Three-section adjustable width track design: save the time of entering and exiting the board and improve the detection efficiency

Stainless steel roller conveyor belt: wear-resistant, strong load, easy to maintain

Automatic cleaning device of detection module: Automatically clean the surface dust to avoid detection interference. Working height can be selected according to the height of the production line

Projection rework station (online/offline)

Avoid manual searching, improve maintenance efficiency, and avoid omissions;

Support single point/multipoint mark bad point mode;

Single point/multipoint projection, high alignment accuracy;

Support multi-station operation and improve maintenance efficiency

A variety of guide color options to avoid color interference on the layout

Guide maintenance in different areas, more efficient;

Flat/inclined maintenance track, can be customized according to customer's situation;

类别 | 项目 | AIS300 | AIS301 |

PCBA板规格 | PCBA尺寸 | 50 x 50mm ~ 550 x 550mm | 50 x 50mm~450 x 400mm (三段式为350*400mm) |

PCBA厚度 | 0.3mm ~ 7 mm | ||

光学&视觉系统 | 元件高度 | 顶面:150mm,底面:25mm | |

PCB形变范围 | 小于4mm | ||

识别方法 | 深度学习智能算法、彩色图像对比、颜色提取、形状匹配、二值化、OCR、一维/二维条码识别、拼板识别、 特征提取、特征点匹配等 | ||

控制系统 | 相机 | 高速彩色500W像素CCD工业相机(1200万可选配) | |

光源 | 环形塔式光源,频闪RGB高亮LED光源 | ||

主机 | 工业电脑主机,lnteli5CPU, 32G内存,256GSSD+2T硬盘 | ||

检测功能 | 显示器 | 22'FHD高清显示器 | |

功能 | 远程控制、远程协助、gerber文件导入、自定义模型训练 | ||

检测内容 | 检测内容 | 多锡、少锡、连锡、不出脚、空焊、锡洞、缺件、反向、立碑、偏移等 | |

外观&电气参数 | 外形尺寸(长x 宽X咼) | 1100x 1400x 1300 (不含报警灯,高度可微调) | 1100x 1200x 1330 (不含报警灯,高度可微调) |

重量 | 890Kg | 700Kg | |

气压要求 | 0.5 〜0.7MPa | ||

效率及精度 | 电源 | 〜220VAC,50/60Hz,额定功率1000W | |

环境要求 | 温度:10〜45°C,湿度:30〜85%RH | ||

FOV | 45 x 37mm | ||

效率 | 230ms / FOV | ||

|精度 | 20um/像素; | ||